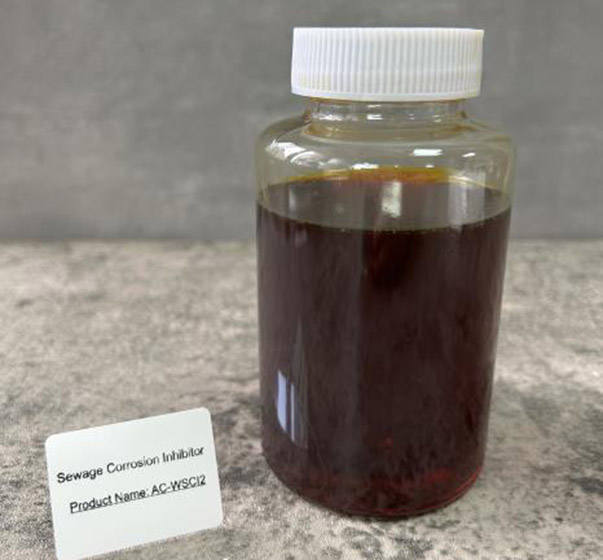

Oil&Gas Well Corrosion Inhibitor AC-WSCI2

Product Detail:

During the production process of oil and gas fields, brine containing CO2 and H2S is accompanied by natural gas output has a significant impact on the materials of oil and gas well equipment such as oil pipes, casings, gas pipelines, etc.Corrosion has a serious impact on the normal production of the entire gas field. CO2 induced steel rapid comprehensive corrosion and severe local corrosion lead to early occurrence of pipelines and equipment corrosion failure with serious consequences. In addition, CO2 is present in natural gas condensate wells.It can cause deep pit corrosion, mossy corrosion, and erosion. To address the above issues, we comprehensively analyzed the corrosive media containing CO2 and H2S in the gas field, as well as the corrosive media containing desorbed water and inorganic salts, and finally determined the AC-WSCI2 corrosion inhibitor formula and synthesis process. AC-WSCI2 corrosion inhibitor combines the advantages of imidazoline corrosion inhibitors, organic amine corrosion inhibitors, and quaternary ammonium salt corrosion inhibitors. It has no special irritating odor, good thermal stability, and low toxicity. It has a significant corrosion inhibition effect on systems containing CO2, H2S, and inorganic salts. It can be miscible with oil in any proportion and has good dispersion performance in high salinity water without affecting the physical, chemical and processing properties of crude oil.

Features:

Excellent anti-corrosion rate with low dosage.

No special irritating odor, good thermal stability, and low toxicity.

Highly effective against corrosive media such as CO2, H2S, and inorganic salts.

Good water solubility and miscible with oil in any proportion.

Application :

AC-WSCI2 oil&gas well corrosion inhibitor has excellent anti-corrosion ability in oil, water, and gas phases, especially suitable for anti-corrosion of high acid value crude oil, natural gas with high sulfur content, or associated gas. It is also suitable for anti-corrosion of oil pipes and casings.

Parameters:

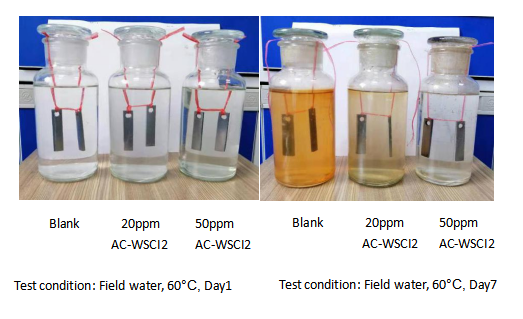

| Product Name | Dosage | Temperature | Field water composition | Required Corrosion

Rate |

Actual

Corrosion Rate |

Test Standard |

| AC-WSCI2 | 20-200pmm | 40-80°C | The partial pressure of CO2 is 0.03mpa, and partial pressure of N2 is 1.97mpa. | Corrosion

speed≤0.076mm/a |

0.021mm/a | PetroChina standard SY/T

5273-2014 |

| Corrosion inhibition

rate≥70% |

83.6% | |||||

| Pass CO2 gas to Field water to make CO2 reach 500mg/L | Corrosion

speed≤0.076mm/a |

0.026mm/a | PetroChina standard

Q/SY 126-2014 |

|||

| Field water | Corrosion inhibition

rate≥70% |

82% | Sinopec standard

Q/SHCG7-2017 |